SILEX TM 55

TECHNICAL WRITE UP OF SILEX TM 55 STYRENATED CARDANOL PHENOLIC RESIN

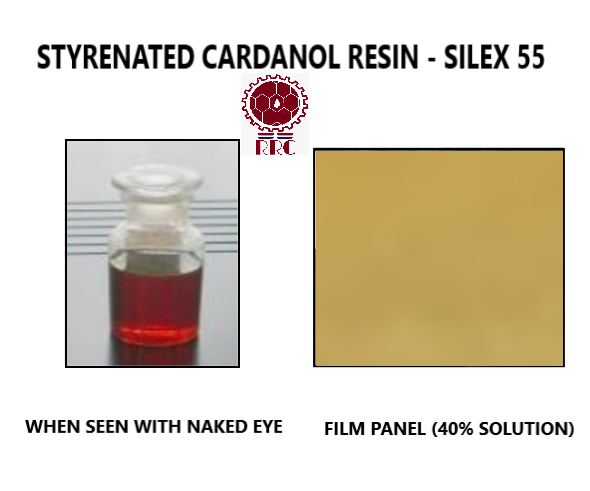

INTRODUCTION: SILEX TM 55 is Card Phenol based Phenolic Resins modified with Styrene. They are Golden yellow resins and are suitable for manufacturing Synthetic Hard Gloss Semi Darker & Darker Enamel Paints, Insulating Varnishes and Aluminum Medium having outstanding Film Properties. They can be blended with any conventional alkyds and can be used for making Lighter colour shades also.

Compatibility: These resins are compatible with all drying oils in all proportions like Linseed Oil, DCO, Soya etc., Their compatibility with other resins like Alkyds, Epoxies is also very good.

Solubility: Silex TM 55 are soluble in most of the Aromatic & Aliphatic hydrocarbon solvents like Mineral Turpentine Oil (MTO), Xylene, Toluene, Solvent Naphtha etc.

Recommended Driers: Driers such as 0.5% Lead or Zirconium, 0.5% Cobalt and 1% Manganese as metal on the solid resin content is recommended. If required, the proportion of driers can be further increased by 1.0% with beneficial effects. After addition of driers ageing for 24 hours is recommended.

Mode of Supply: It is supplied in 200 kg’s packing as 100%, 80%, and 70% solids. For most of the paints and varnishes applications 70% execution is recommended as it has the best film properties & flowable from drums.

Application Technique: Film of Silex TM-55 can be applied either by brush, spray or flow technique.

Storage: The storage stability is Silex TM-55 is infinite if stored in air tight containers in a cool place.

Recommended uses: Silex TM-55 either alone or in combination with other resins are used for formulating quick drying primers, quick drying dark coloured enamels and paints, insulating varnishes, knifing putty, Black offset Printing inks and similar other applications including special purpose anti corrosive paints baking composition etc.

Caution: Some times Silex TM-55 may be used along with basic pigment like Zinc Chrome, Zinc Oxide, basic lead sulphate etc. It is advised that these pigments are not ground along with the main pigment in the resin as there is a possibility of reaction. The reactive pigments should be added after the grinding for proper dispersion of the Pigment. Hence it is advisable to grind the main pigments with any Long Oil Alkyd Resin and then add our resin outside and stir well to avoid reaction.

Technical Specifications