SILEX TM 70

TECHNICAL WRITE UP OF SILEX TM 70 PLAIN CARDANOL PHENOLIC RESIN

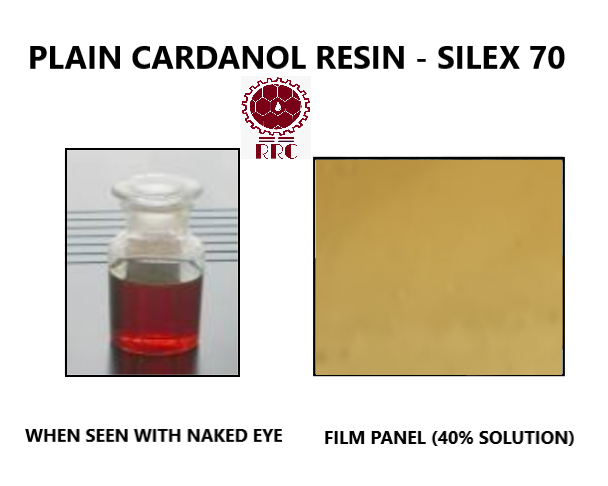

INTRODUCTION: SILEX TM 70 is Plain Card Phenol based Phenolic Resin. They are Golden yellow in colour and are suitable for manufacturing Synthetic Hard Gloss Semi Darker & Darker Enamel Paints, Insulating Varnishes, Aluminum Medium etc., & are having outstanding Film Properties. They can be blended with any conventional Alkyds and Epoxies & can be used for making Lighter colour shades also & specially recommended for Marine Paints.

SILEX TM 70 has excellent resistance to the softening effects of mineral oils and high resistance to acids and Alkalis. They have antibacterial and insecticidal properties and good compatibility with other synthetic resins, such as alkyds, chlorinated epoxy rubber, Phenolic resins, etc. They can be used as raw materials for various paints. They are used to achieve the required gloss and flexibility, as well as having good mechanical strength, quick drying ability, rust and corrosion inhibiting properties, excellent resistance to water, acids, Alkalis and other chemicals. Cardanol-based resins are used as substitutes for alkyds in enamels and phenol in Phenolic resins.

Silex TM 70 is used to achieve the required gloss, elasticity as well as good mechanical strength, have the ability to dry quickly, have anti-rust and corrosion inhibiting properties, excellent resistance to water, acids, Alkalis and other chemicals Used in the substitution reaction of alkyds in enamels.

COMPATIBILITY: These resins are compatible with all drying oils in all proportions like Linseed Oil, DCO, Soya etc., Their compatibility with other resins like Alkyds & Epoxies is also very good.

SOLUBILITY: SILEX TM 70 is soluble in most of the Aromatic & Aliphatic hydrocarbon solvents like Mineral Turpentine Oil (MTO), Mineral Spirits (MS), Xylene, Toluene, Solvent Naphtha etc.,

RECOMMENDED DRIERS: Driers added are 1% Lead, 0.5% Cobalt & 1.5% Manganese as metals in their Octoate and the varnish is left for 24 hours for ageing. These resins have very good film forming property like high gloss, better hardness and water/chemical resistance. These properties are beneficial to paint manufacturers as Card phenol resin is economical compared to conventional Alkyds. However pure Card phenol resin can be incorporated in regular paint formulation to reduce cost and adjust quality.

MODE OF SUPPLY: It is supplied in 200 or 25 kg’s packing’s as 100%, 80%, and 70% solids in MTO. For most of the paints and varnishes applications 70% execution is recommended as it has the best film properties.

RECOMMENDED USES: High Gloss Red oxide metal primer made with Card phenol resin does outstanding performance and corrosion protection. In making economical quality interior enamels Card phenol resin is added to reduce cost of formulation and also improve gloss. Incorporating Long oil alkyd in Card phenol formulation improves flexibility and durability. Card phenol resin based formulations tend to yellow when exposed to sunlight and the shade of the paint darkens hence not recommended for exterior finishes. Suitable for Offset Printing inks, Insulating Varnishes etc.,

STORAGE: The storage stability of SILEX TM 70 Resins are infinite if stored in tight containers in a cool place.

CAUTION: Some times SILEX TM 70 may be used along with basic pigment like Zinc Chrome, Zinc Oxide, basic lead sulphate etc. It is advised that these pigments are not ground along with the main pigment in the Card phenol resin as there is a possibility of reaction. The reactive pigments should be added after the grinding for proper dispersion of the Pigment. Hence it is advisable to grind the main pigments with any Long Oil Alkyd Resin and then add our SILEX TM 70 resin outside and stir well to avoid reaction.

Technical Specifications